Introduction For Automatic CNC Saw Blade Brazing Machine

What is the differece between Automatic CNC Saw Blade Brazing Machine compare with normal manual saw blade welding?

Firstly, with the progress of the times, the pay grade for skilled saw blade soldering workers will only become increasingly expensive over time. From the perspective of circular saw blade production efficiency, the production efficiency of a fully automatic CNC saw blade soldering and brazing machine is equivalent to ten skilled workers using a high-frequency machine to solder and weld the carbide tips on the circular saw blades head. The efficiency improvement of fully automate saw blade welding machines is astonishing.

Automatic CNC Saw Blade Brazing Machine Achieve better quality control for circular saw blade production

From the perspective of welding quality of the carbide tips, the quality of manually welded carbide tips cannot be compared to fully automatic brazing machines. Fully automatic saw blade brazing and soldering machine, the operator can adjust the brazing temperature at any time, and the additional tempering function after saw blade brazing and soldering will also make the blade’s quality more stable.

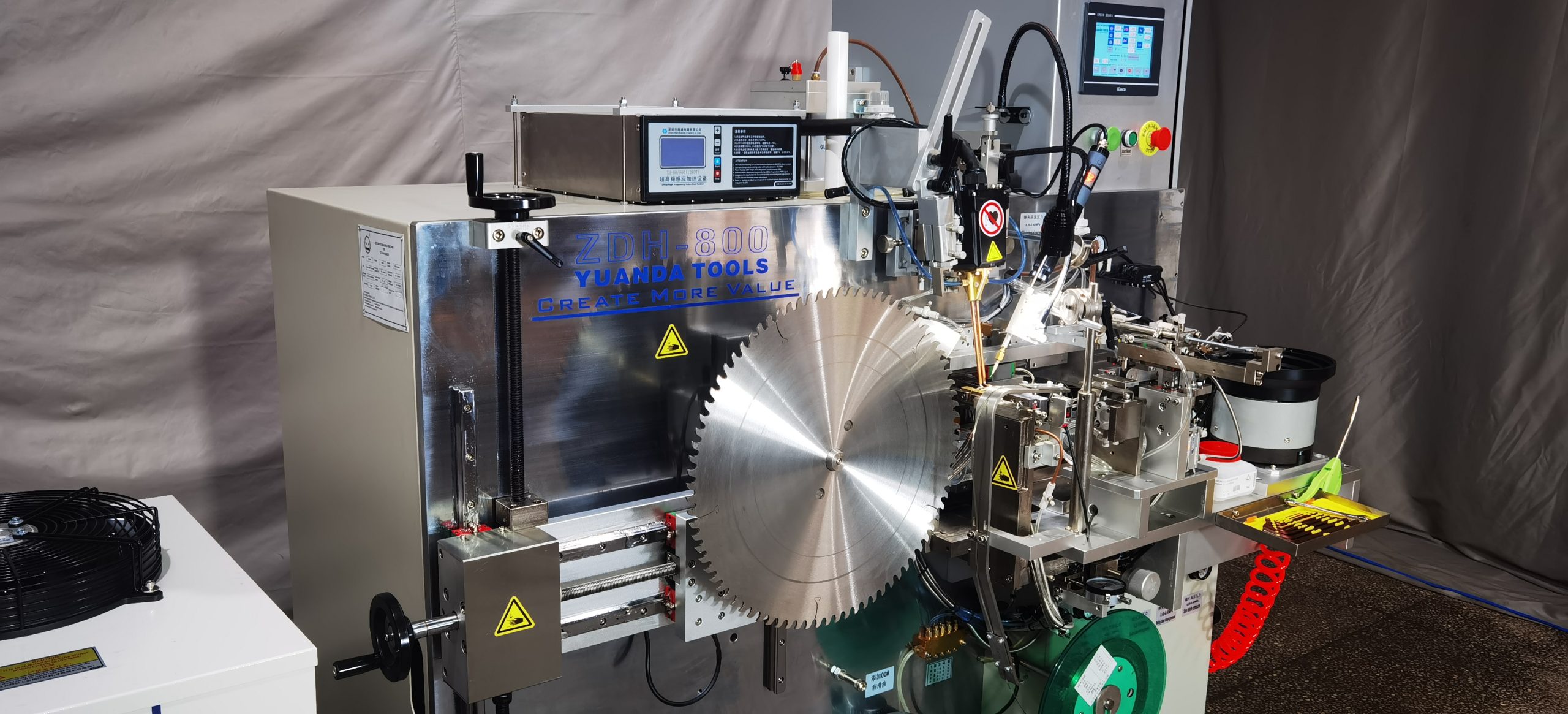

Besides this, our ZDH-350 ZDH-800 ZDH-1400 automatic cnc saw blade brazing and soldering machine models can all adjust the carbide tip alignment and centering to the saw body, which is can not control by manual saw blade brazing and soldering.

Automatic CNC Saw Blade Brazing and welding Machine requirements for the operating environment

In order to provide better quality control for the production of circular saw blades, as one of the most core processes in the production of circular saw blades, the firmness of carbide tip brazing, soldering and welding is the most important. Therefore, we need to provide necessary environmental support for the automatic cnc saw blade brazing and soldering machine as much as possible.

- Firstly, a flat ground is necessary to avoid the vibration generated by the automatic cnc saw blade brazing and soldering machine during operation from affecting the welding quality.

- Secondly, it is necessary to provide compressed air for the automatic cnc saw blade brazing and soldering machine, preferably filtered and dehydrated compressed air, to provide a stable working air source for the saw blade brazing machine.

- Finally, it is recommended to reserve sufficient space at the rear of the saw blade brazing machine to provide a stable heat dissipation environment for ultra-high frequency heating unit.

heating unit and cooling unit of Automatic CNC Saw Blade Brazing Machine

The automatic cnc saw blade brazing and soldering machine requires fast heating energy, so the heat source is a 6kw ultra-high frequency heating machine and matched with a water chiller to cool the heating unit. If the cooling unit malfunctions or the cooling water does not flow, the automatic alarm system of the automatic cnc saw blade brazing and soldering machine will prompt the operator to avoid accident happens.