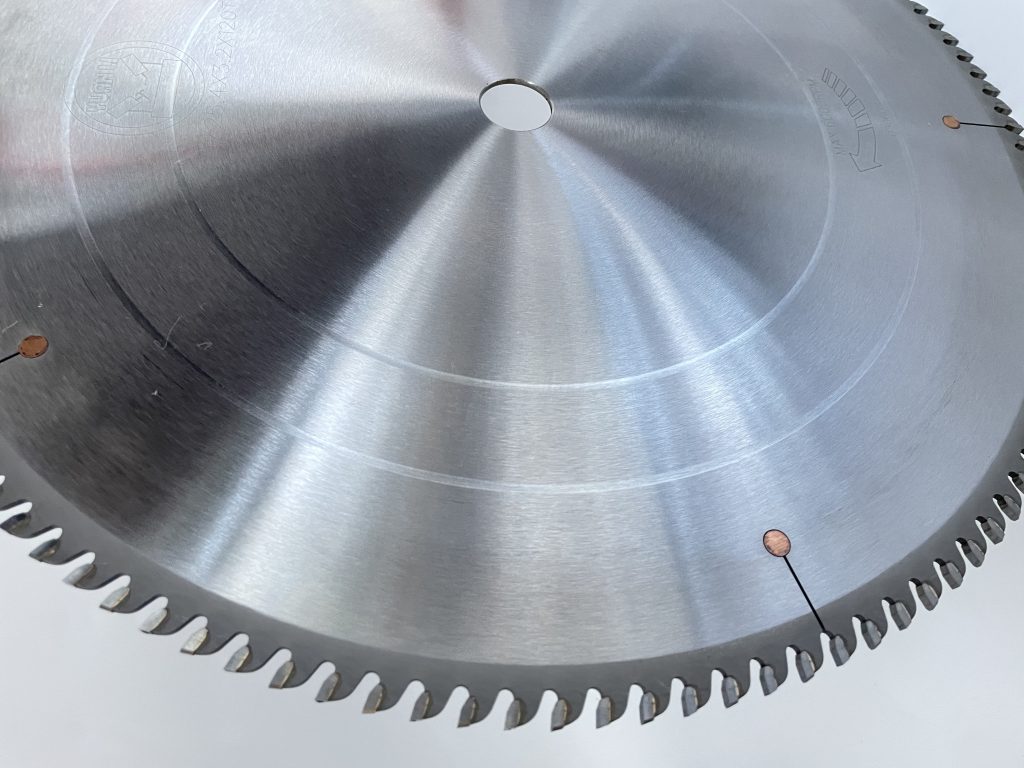

How Can We Produce Good Quality Circular Saw Blade?

Yes,many of you can produce circualr saw blade, but for a good quality one, how can we achieve it? Besides having automatic saw blade sharpening machine, automatic saw blade brazing machine, what else do we need? In the following, Yuanda tools saw blade master will explain to you about the key knowledge of the carbide tip circular saw blade production.

Raw material selection for circular saw blade

Commonly used steel for saw blade body is 65Mn, 75Cr1 and SKS51. The following I would like to tell you why many saw blade manufacturer fail to produce good quality saw body with Chinese steel compare with the German hardened and tempered 75Cr1 steel sheets. It’s not that simple as you think.

The German 75Cr1 material provided by Bestar or other supplier, the furnace to produce the steel sheet is call “Enber”, the production line contains heating-hardening-tempering-roll leveling/flattening,the production line can provide 75Cr1 steel sheet upto 500mm.

Material: We need to admit that China made steel for saw blade production is not as good as Germany. But I would say the quality is close after proper technique and heat treatment process and good enough to produce strobe saw/wood working saw/metal saw. When it comes to 75Cr1 thin steel sheet to produce saw body,I don’t suggest you to buy raw materials from China as you done before,it would be a waste of money. Plus,Chinese customs do not encourage the export of steel product.

The best way is to deal with China made 75Cr1 is you can order finished saw blanks from us and Leniv do the laser cut after you receive it. We usually buy hot rolled steel from the steel plant,we got a partner proceed annealing the steel again then cold roll it again. Such process can called “prepare works” before hardened and tempering,which requires special furnace and machine not the normal furnace we commonly use can do that.

heat treatment process for circular saw blade

The saw body need to endure hardening and tempering. China made 75Cr1 steel requires higher final HRC hardness than German made 75Cr1 steel, which requires lots of experience in actually work experience. In China, due to the difference of heattreatment furnace to Germany. Peopple usually use salt bath to harden the saw body. The temperature uniformity of the saw blank in the salt bath is very good, and the hardness after heattreatment uniformity is also good.

circular saw blade Body quality control

As to the quality for circualr saw blade body, the runout and flatness is everything. The another factor which will greatly affect the saw blade’s quality is the flatness after hardening and tempering. Basically,all the saw manufacturers understand the best way is to control the flatness of the saw blanks during quenching and pressure tempering,not by hammering/saw smithing after heattreatment,much man hammer on the saw would bring too much unwanted tension to the saw body. During the saw blade is being tempered, our furnace will have two pressure plate to lay pressure to the saw blank to flatten the saw body,such equipment you don’t have it in Ukraine.

circular saw blade Body tensioning

Tension is the key factor that keeps the saw blade running straight during saw blade in high speed rotation. You can order saw blade and saw body with tension or without roll tensioning from Yuanda Tools.