M

Our Materials

Whether it is the TCT carbide and steel used in the production of circular saw blades and cutting tools, or the components of machines, we have carefully selected to ensure the best quality..

tungsten TCT Carbide

tCT carbide

High quality TCT carbide tip is a guarantee of excellent cutting ability for circular saw blades and milling cutters. We will choose corresponding high-quality carbide tips for different circular saw blades according to customer usage scenarios. We can provide ceratizit and high-quality hard alloys produced by Chinese suppliers to provide customers with the highest cost-effectiveness choice.

steel

steel

Quality steel is the guarantee for producing higher quality saw bodies, and good quality saw body is the foundation to produce high-quality circular saw blades. We use high-quality steel such as Germany DIN 75Cr1, Japannese SKS51. All steels used for circular saw blade and cutting tools production undergo careful heat treatment after laser cutting to achieve optimal performance.

Technique

Production Engineering

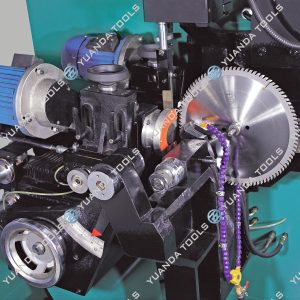

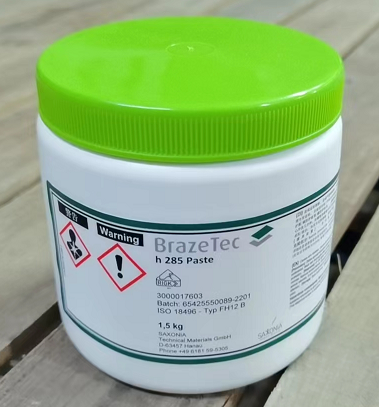

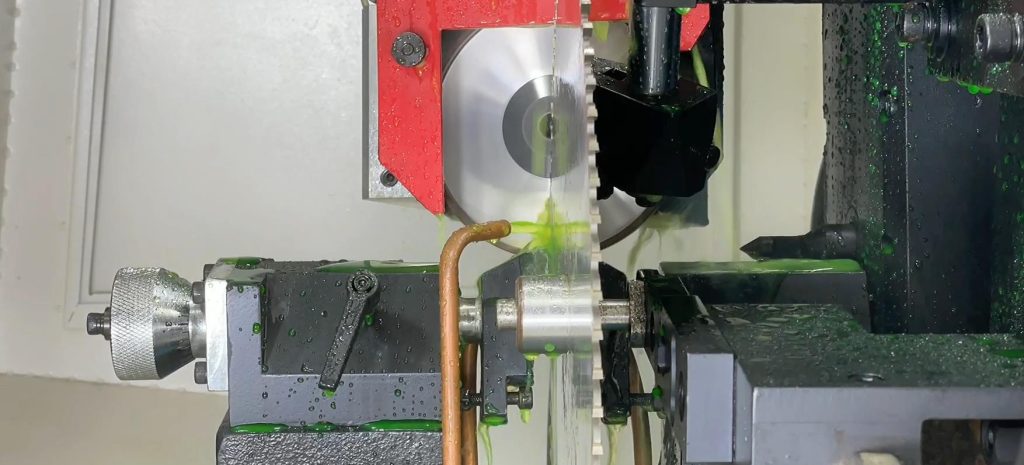

The circular saw blade undergoes multiple processes to ensure stable quality: Heat treatment, roll leveling, roll tensioning, soldering, top and face sharpening, double side sharpening, sand blasting, surface polishing, manual flattening and finally passing the examination by our quality control department.

qC

Quality control

As a professional circular saw blade manufacturer, each saw blade produce by Yuanda Tools undergoes full inspection by our quality control department before being submitted to our customers.

angle

Angle testing

Size

Run out testing

test

hardness testing

B

Best Seller Product

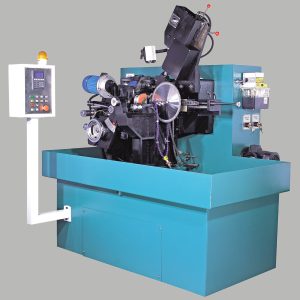

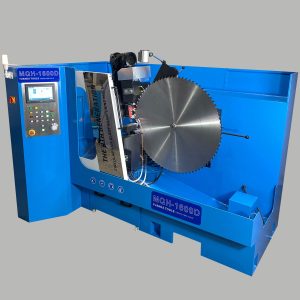

In addition to the production of circular saw blades, we also provide various types of equipment for the production of circular saw blades