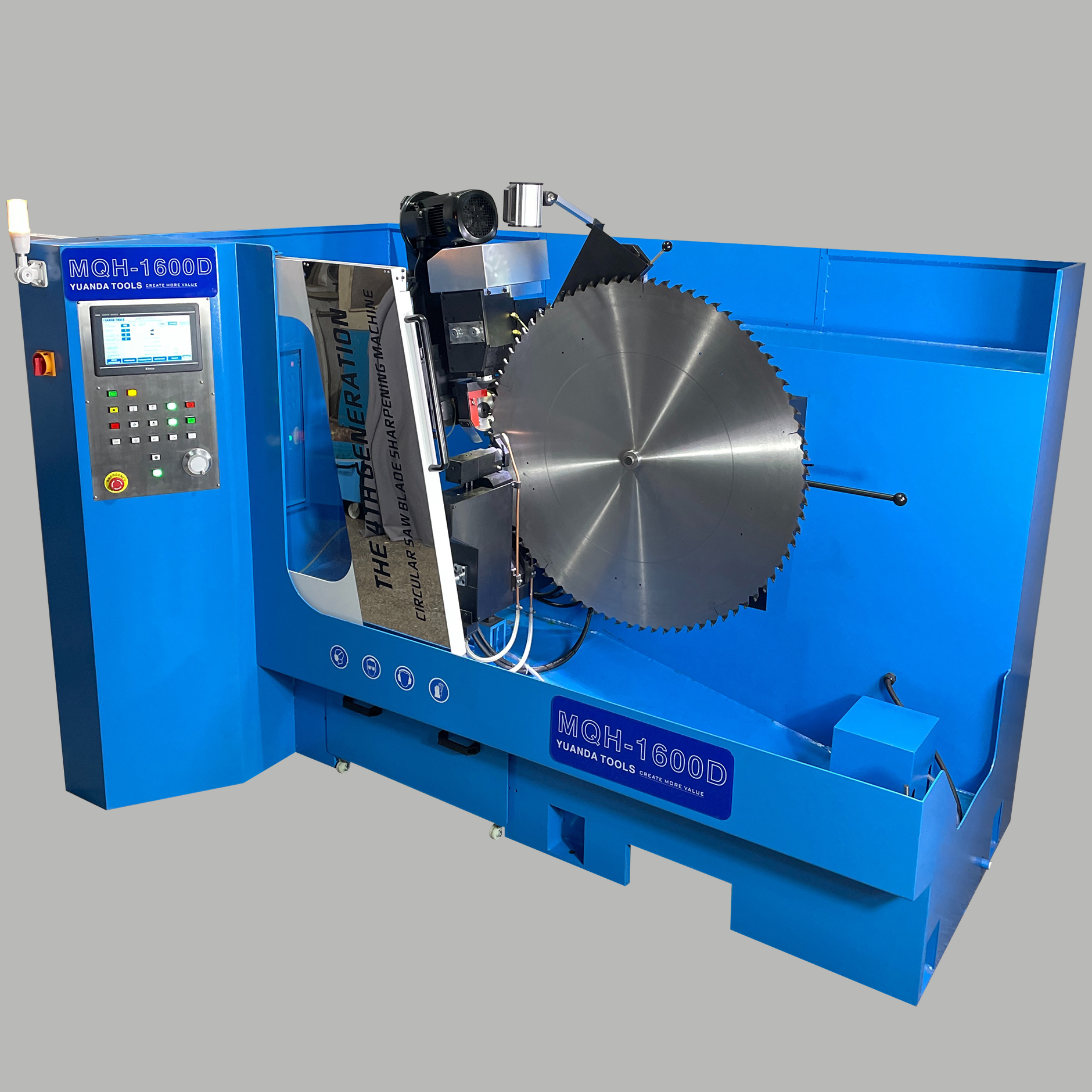

MQH-1600D Automatic Top And Face TCT Saw Blade Sharpening Machine

Your reliable partner

- Free technical support throughout lifecycle

- Model with reliable performance

- Long service life

Description

MQH-1600D Top and face automatic circular TCT saw blade grinder is it the latest 4th generation saw blade sharpening machine launched by yuandatools.

The latest Yuanda Tools fourth generation D-series machine has retained the high precision, high rigidity and long service life of the third generation C-series MQH model. The CNC level of the MQH-1600D automatic saw blade sharpening machine has been further improved. The grinding head angle rotation mechanism and saw blade’s tooth setting mechanism are controlled by servo motors. Operator only needs to input the corresponding parameters on the touch screen human-machine interface to complete the setting: Directly input the bevel angle value and tooth pitch value. The fourth generation D series circular saw blade sharpening machine will no longer require the use of mechanical structures to adjust parameters like the third generation model.

MQH-1600D Top and face automatic saw blade sharpening machine, also know as saw blade grinding machine and saw blade grinder, is made up of a frame, servo drive system, electric control system and a hydraulic system. The machine is designed for different kinds of tooth type in the processing of circular TCT saw blade. The operator only need to choose the tooth type on the interface and input relevant parameters,then the machine will grind all the teeth automatically and finish the whole procedure.

The MQH-1600D automatic top and face TCT saw blade sharpening machine can produce and resharpen saw blades range from 300mm to 1600mm. Several automatic saw blade sharpening machines can be operated simultaneously by one person. It is characterized by high automation and precision, quick efficiency and convenient adjustment. This machine is suitable for mass production of saw blades by the manufacturer and for the regrinding service of used saw blades.

Machine Feature

- High strength castings that have undergone heat treatment and natural aging ensure the accuracy and stability of the mechanical structure

- Sharpening precision lasting

- Long service life

- 3 axis servo control

- Big tooth pitch up to 100mm available

- Servo control grinding head rotation, angle value directly input on touch screen

- Tooth profile edit function

- Program saving function

- Full automatic circle saw blade sharpening

technical Parameter

Saw Blade Grinding Diameter 300-1600 mm

Saw Blade Tooth Pitch 8 to 100 mm

Saw Blade Thickness 1 to 10 mm

Grinding Head Feed Rate 2 to 6 mm/min

Face Angle/Hook Angle -5 to +40°

Top Angle/Clearance Angle +10 to +30°

Grinding Head Rotary Angle -45 to +45°

Total Power 4.0kW

Voltage and Frequency Standard 380V 50Hz 3Phase(Custom made available)

Grinding head motor Power 1.1kW

Oil Pump MotorPower 0.75kW

Swing Angle Motor Power 0.55kW

Lubrication Pump Power 0.06kW

Length 2500 mm

Width 1350 mm

Height 1900 mm

Net Weight 1700 KG

Gross Weight 1765KG

Grinding Wheel size Ø125 x Ø32

Coolant Tank Capacity 150L

operation video

In order to let customers more familiar with and master how to operate the automatic saw blade sharpening machine, we have specially produced a operation instruction video for the MQH-1600D Automatic circular TCT saw blade sharpening machine , as shown below: