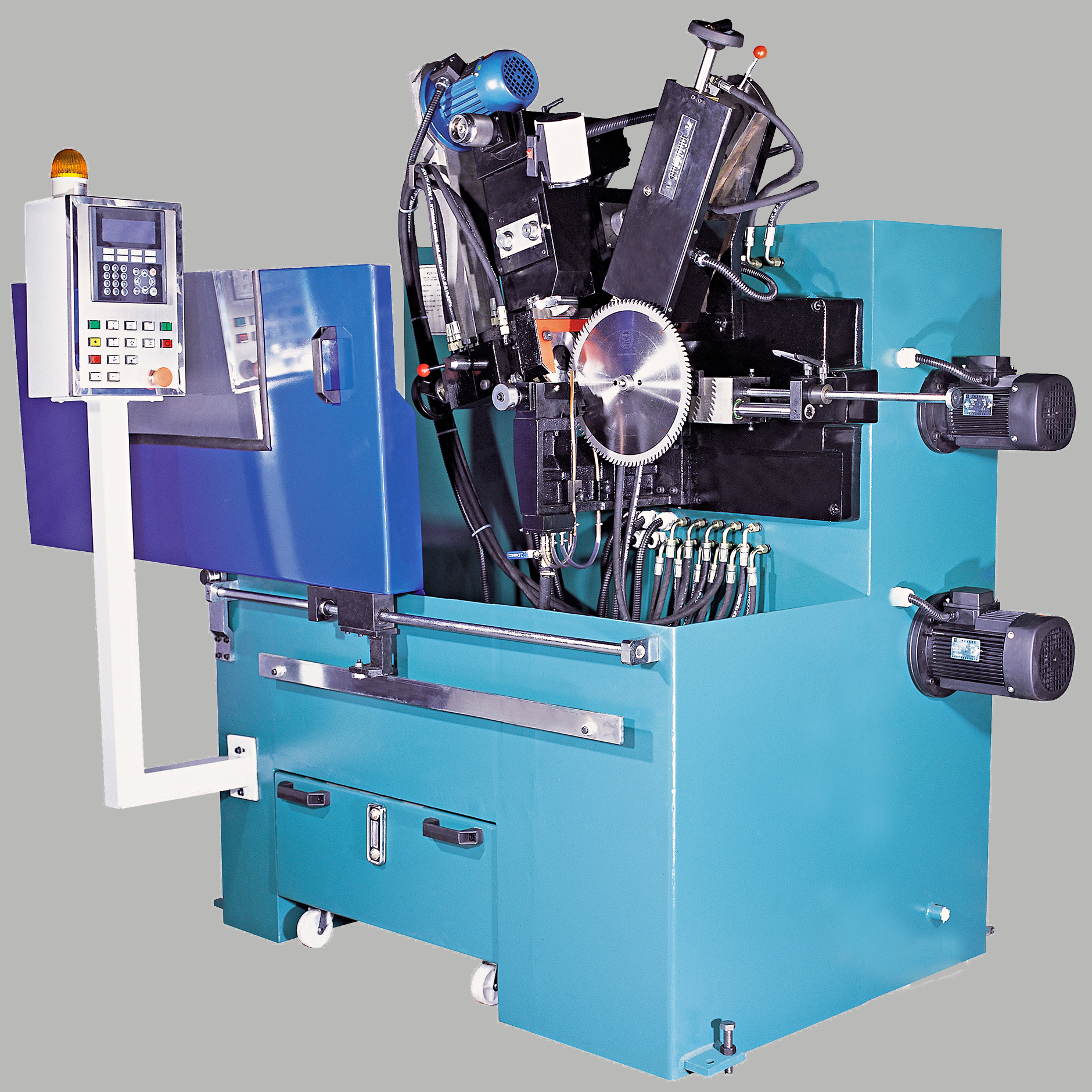

MQH-600B Automatic Top And Face TCT Saw Blade Sharpening Machine

Your reliable partner

- Free technical support throughout lifecycle

- Model with reliable performance

- Long service life

Description

MQH-600B automatic top and face circular TCT saw blade sharpening machine is the second-generation saw blade grinding machine of Yuanda Tools. We have stop the production of the 2nd generation MQH-600B series saw blade top and face grinding machine since 2012.

For customers who are still using MQH-600B circular saw blade grinder, Yuanda Tools will continue to provide operational guidance, component supply, and software support services. Please contact the professional after-sales technical engineer of Yuanda Tools to resolve any possible technical issues.

If you are still using this classic automatic saw blade sharpening machine and wants to extend the service life of your machine, YuandaTools also provides remanufacturing and upgrading services for old saw blade sharpening machine for models like MQH-600B. Customers can choose to send the machine back to Yuanda Tools saw blade sharpening machine factory, and we can upgrade and remanufacture your 2nd generation MQH-600B automatic top and face circular TCT saw blade sharpening machine to an 3nd generation MQH-600C automatic top and face circular TCT saw blade sharpening machine.

Major maintenance and upgrading projects Items

Upgarde from MQH-600B to MQH-600C level Saw blade sharpening machine

Mechaical Parts

- Saw blade sharpening machine frame repainting (Optional)

- Saw blade sharpening machine grinding head mechanism

- Saw blade sharpening machine grinding head feeding mechanism upgrade from manual feed gear box to stepper motor

- Saw blade sharpening machine grinding head motor(Optional)

- Replace all the bearings on the saw blade sharpening machine

- Linear guide ways

Hydraulic System

- Hydraulic oil pump

- Hydraulic oil pump motor(Optional)

- Hydraulic oil pump oil pipe

- Hydraulic oil pump filter

- Replace all the oil seals on saw blade sharpening machine

Electrical system

- The whole electrical control circuit

- Operation panel box

- All the control buttons on the operation panel

- Upgrade from original Misubishi text display screen to Siemens touch screen HMI

- Upgarde to automatic lubrication pump(Optional)

Yuanda Tools Rebuild process Of Saw Blade Sharpening Machine

- Firstly, after the old saw blade sharpening machine been deliver to our factory, the sharpening machine will be dismembered by Yuanda Tools’s experienced engineering team, and all mechanical parts on the saw blade grinding machine will be dismantled and thoroughly cleaned.

- After cleaning, the saw blade sharpening machine’s frame will be repainted after removing rust.

- According to the customer’s budget, Yuanda Tools’s electrical engineers will replace aged electrical components or replace all the electrical components of the saw blade sharpening machine after completing the machine circuit inspection.

- All the mechanical parts took off from the original saw blade grinding machine will be tested by Yuanda Tools’s mechanical engineer, the parts being examed and consider it is still qualified will be continue to use after removing rust and phosphating if necessary, the wear mechanical parts of the machine will be replaced with new ones. All the linear guide ways and ball screws of the original saw blade sharpening machine will be replaced.

- After the saw blade sharpening machine passed through the rebuild process, the final in house testing and debugging will be carried out before deliver to the client. After the trial saw blade sharpening test, Yuanda Tools’s professional technical team will evaluate the effectiveness and accuracy of grinding.

- Clients will recieved a saw blade sharpening machine from Yuanda Tools, almost the same as a new one.

Technical Parameter

original parameter of yuanda tools mqh-600b automatic circular tct saw blade sharpening and grinding machine

Saw Blade Grinding Diameter 100-600 mm

Saw Blade Tooth Pitch 8 to 70 mm

Saw Blade Thickness 1 to 10 mm

Grinding Head Feed Rate 2 to 6 mm/min

Face Angle/Hook Angle -5 to +40°

Top Angle/Clearance Angle +10 to +30°

Grinding Head Rotary Angle -45 to +45°

Max Grinding Speed 20 tooth/min

Oil Pump Pressure 4 Mpa

Total Power 1.5W

Voltage and Frequency Standard 380V 50Hz 3Phase(Custom made available)

Grinding head motor Power 0.55kW

Oil Pump MotorPower 0.37kW

Swing Angle Motor Power 0.37kW

Length 1620 mm

Width 1350 mm

Height 1900 mm

Net Weight 850 KG (Half cover model), 950 KG(Full cover model)

Gross Weight 1000KG (Half cover model), 1050 KG(Full cover model)

Grinding Wheel size Ø125 x Ø32

Coolant Tank Capacity 80L