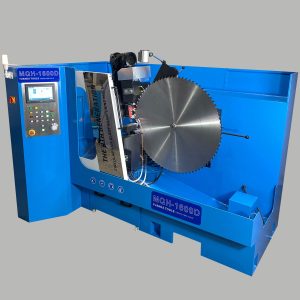

Automatic Saw Blade Sharpening Machine Blade Clamp, Automatic Saw Blade Grinding Machine Blade Clamp, Accessories

Your reliable partner

- Free technical support throughout lifecycle

- Model with reliable performance

- Long service life

Description

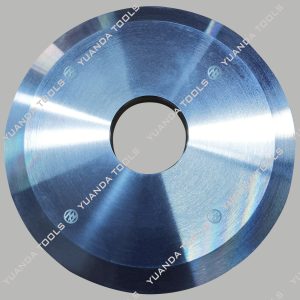

In the sharpening process of TCT circular saw blades, in addition to the need for the bore of the TCT circular saw blade to be fixed on the hanging core shaft with a ring that meets the tolerance, the accuracy of the blade clamp and the positional tolerance also affect the quality of sharpening.

Let’s explain why the blade clamp mechanism is so important based on its working principle.

- When designing a clamping mechanism for the TCT saw blade sharpening and grinding machine, only the position of one side of the clamping mechanism is fixed, and the other side of the clamping mechanism will be fasten when needed. So the two blade clamp blocks need to be installed on the same horizontal line.

- In addition, the flatness of the two saw blade clamping blocks is very important. The surface of the saw blade clamping blocks needs to be perfectly fitted with the saw blade body, otherwise it may cause an increase in the radial runout of the sharpened circular TCT saw blade.

- Generally speaking, circular saw blade body are heat-treated and typically have a hardness of around HRC42 to 50. Therefore, the clamping mechanism of the TCT circular saw blade sharpening and grinding machine may experience wear and tear after prolonged use in repeatedly clamping the saw blades. If excessive wear of the saw blade clamping blocks were found, they needs to be replaced in a timely manner.

Yuanda tools provides different types of blade clamping blocks for the automatic saw blade sharpening machines, please contact the sales engineer or after-sales engineer of Yuanda Tools if you need these spareparts. We also provide blade clamp blocks for German automatic TCT saw blade sharpening machines.